UV STERILIZATION

Ultraviolet (UV) sterilization, also known as UV disinfection or UV germicidal irradiation, is a method of using ultraviolet light to kill or inactivate microorganisms such as bacteria, viruses, and fungi. UV sterilization is widely used in various applications to disinfect water, air, surfaces, and equipment.

Here’s how it works:

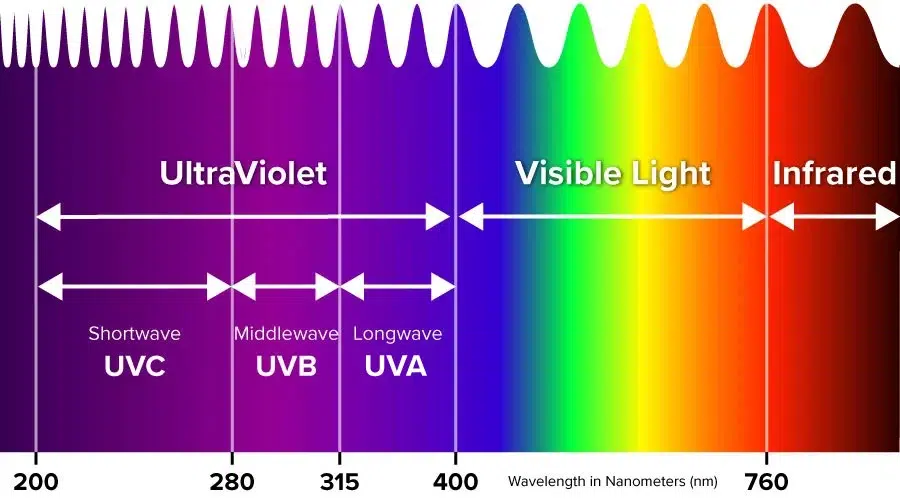

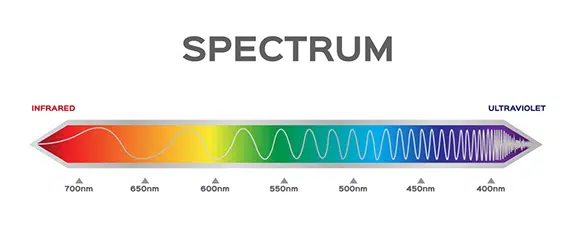

1. UV Light Spectrum: Ultraviolet light is part of the electromagnetic spectrum and is categorized into different ranges based on its wavelength. The UV spectrum is typically divided into three regions:

- UVA (Ultraviolet A): Long-wave UV with the least germicidal properties.

- UVB (Ultraviolet B): Medium-wave UV with some germicidal properties and often associated with skin tanning and damage.

- UVC (Ultraviolet C): Short-wave UV with strong germicidal properties. UVC light is the most commonly used for sterilization purposes.

2. UVC Sterilization: UVC light in the range of 200 to 280 nanometers (nm) is highly effective at disinfection because it damages the genetic material (DNA or RNA) of microorganisms. When microorganisms are exposed to UVC light, their DNA or RNA absorbs the energy from the UV photons, which can lead to mutations, cell death, or the inability to reproduce.

3. UV Sterilization Devices: UV sterilization devices can vary in size and design. Some common examples include:

- UV-C lamps: These are often used in HVAC systems, water treatment plants, and air purifiers to disinfect air and water.

- UV-C handheld devices: These are portable devices that can be used to disinfect surfaces, objects, and small areas.

- UV-C chambers or boxes: These are enclosed chambers equipped with UVC lamps that are used to sterilize objects, such as medical equipment, electronics, and personal items.

4. Applications of UV Sterilization: UV sterilization is used in various industries and settings, including:

- Healthcare: UV sterilization is employed to disinfect medical equipment, hospital rooms, and surgical instruments.

- Water Treatment: UV disinfection systems are used to purify drinking water and treat wastewater.

- Food Industry: UV sterilization can be used to disinfect food and food packaging.

- Air Purification: UV-C lamps are used in air purifiers to kill airborne pathogens.

- Laboratory and Research: UV sterilization is used to maintain sterile conditions in labs.

UV sterilization is a valuable tool for reducing the spread of infections and ensuring the safety of various environments. However, it’s important to use UV sterilization devices properly and ensure that they are maintained and calibrated to be effective in killing microorganisms without causing harm to humans or animals.

A UV sterilizer disinfects water by using ultraviolet (UV) light, specifically UVC light, to kill or inactivate microorganisms present in the water. Here’s how the process works:

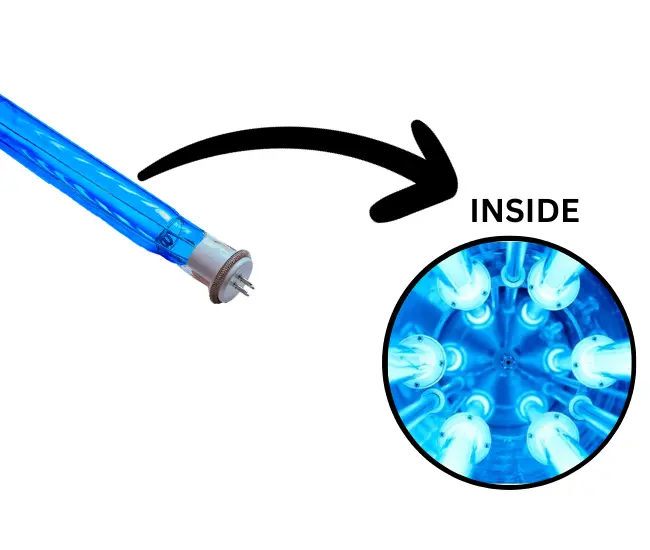

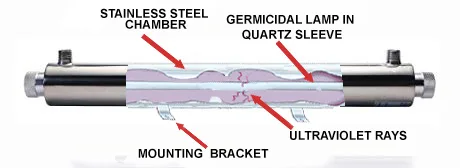

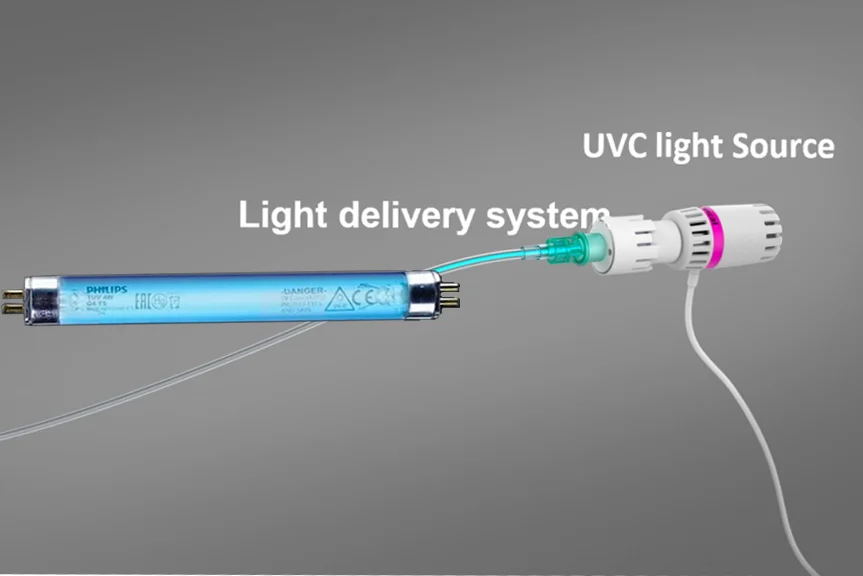

UV-C Light Source: The UV sterilizer is equipped with a UV-C light source, typically a low-pressure mercury lamp or more recently, light-emitting diodes (LEDs). These lamps emit UV light in the germicidal range with a wavelength of around 254 nanometers (nm).

Water Flow: The water that needs to be disinfected is passed through a chamber or a pipe where the UV-C lamp is installed. The water flows around or past the lamp in a controlled manner.

Exposure to UV-C Light: As the water flows through the chamber, it is exposed to the intense UV-C light emitted by the lamp. This UV-C light penetrates the cells of microorganisms that are present in the water.

Effect on Microorganisms: When microorganisms (such as bacteria, viruses, and algae) in the water are exposed to UV-C light, the UV photons are absorbed by the genetic material (DNA or RNA) inside their cells. This absorption of UV energy damages the genetic material, leading to the formation of thymine dimers and other types of genetic mutations.

Inactivation of Microorganisms: The damage to the genetic material disrupts the microorganisms’ ability to reproduce and function properly. It essentially renders them incapable of causing infections or carrying out metabolic processes necessary for survival.

As a result, the microorganisms become inactivated and unable to multiply or cause harm.

Safe, Chemical-Free Disinfection: One significant advantage of UV sterilization for water disinfection is that it does not require the addition of chemicals, like chlorine or ozone, which can leave residual byproducts and alter the taste or odor of the water. UV sterilization is a chemical-free method that leaves no chemical residue in the water.

Monitoring and Maintenance: UV sterilizers must be regularly monitored and maintained to ensure their effectiveness. Over time, the UV lamps can degrade, and the quartz sleeves or tubes that protect the lamp may accumulate deposits that reduce UV transmission. Proper maintenance and periodic replacement of UV lamps and sleeves are essential for consistent performance.

UV sterilization is commonly used in various water treatment applications, including drinking water treatment, wastewater treatment, swimming pool and spa disinfection, and aquaculture. It is an effective and environmentally friendly method for disinfecting water, ensuring that harmful microorganisms are eliminated without introducing chemical contaminants into the water supply.

UV sterilization has limitations and does not remove all types of bacterial contamination from water. While UV sterilization is highly effective against many bacteria and viruses, it may not be equally effective against all types of microorganisms and contaminants. Here are some factors and limitations to consider:

Microbial Resistance: Some bacterial species and strains are more resistant to UV radiation than others. For example, spore-forming bacteria such as Clostridium and Bacillus can be more resistant to UV disinfection. In such cases, higher UV doses or alternative disinfection methods may be needed.

Protozoa and Cysts: UV radiation may not effectively inactivate certain protozoa, such as Cryptosporidium and Giardia, and their cysts. These microorganisms have protective outer layers that can shield them from UV light. Additional treatment methods, like filtration, may be required to address these specific contaminants.

Water Quality: UV disinfection can be less effective in turbid or cloudy water, as suspended particles can block or scatter UV light. Pre-filtration or clarification of water may be necessary to improve UV disinfection performance.

UV Dose: The effectiveness of UV sterilization depends on the UV dose delivered to the microorganisms. Proper system design and sizing are crucial to ensure that the required UV dose is achieved and maintained. Low UV doses or inadequate contact time can result in incomplete disinfection.

Maintenance: UV lamps degrade over time and need regular replacement to maintain their effectiveness. Routine maintenance and monitoring of UV sterilization systems are essential to ensure optimal performance.

Secondary Effects: While UV disinfection directly targets microorganisms, it may have secondary effects on water quality. UV exposure can lead to the formation of disinfection byproducts, although these are typically at much lower levels than those associated with chemical disinfection methods like chlorination.

Limitation to Surface/Area Treated: UV sterilization treats the water that comes into direct contact with the UV light source. It may not address biofilms or microorganisms that are shielded from direct UV exposure by complex plumbing or equipment.

Given these limitations, UV sterilization is often used as part of a multi-barrier approach to water treatment. This approach combines UV disinfection with other treatment methods such as filtration, chlorination, and ozonation to provide comprehensive water purification and ensure the removal or inactivation of a broad spectrum of contaminants, including bacteria, viruses, protozoa, and non-biological impurities.

The specific design and implementation of a water treatment system depend on the quality of the source water and the desired level of treatment. Water treatment professionals consider these factors when selecting and designing treatment systems to meet water quality objectives effectively.