RO Plant For Hospitals

Get the best results of your water today !

Ready to solve your water quality issues with a custom RO solution? Contact us today for a free consultation or a tailored quote for an RO plant system. Our team is here to help you enjoy cleaner, safer, and healthier water at Hospitals

Benefits of Centralized RO Plant Over Multiple Domestic Units

Economies of Scale:

A 500 or 1000 LPH centralized RO plant serves more people efficiently, reducing purification costs and offering long-term savings.

Reduced Maintenance Costs:

A 500 or 1000 LPH centralized RO plant reduces maintenance costs and effort compared to multiple small units, streamlining service and upkeep.

Lower Initial Investment:

Though the upfront cost is higher, a 500 or 1000 LPH centralized RO plant is more cost-effective long-term than multiple domestic units.

Reduced Energy Consumption:

A 500 or 1000 LPH centralized RO plant offers better energy efficiency and lower operational costs than multiple domestic units.

Better Control and Monitoring:

A 500 or 1000 LPH centralized RO plant enables efficient monitoring, proactive maintenance, and better water management for long-term savings.

Longer Lifespan and Durability:

A 500 or 1000 LPH centralized RO plant is more durable than domestic units, built for high usage and longer lifespan, reducing replacement costs.

Features of RO Plant for Hospitals

- Compact design, well suited for Hospitals

- Designed with automatic backwash systems, so no more daily headaches

- Quick Installation and On-Call service

- Designed to work without an anti-scalant system, No chemicals needed.

- Low maintence and Zero intervention needed!

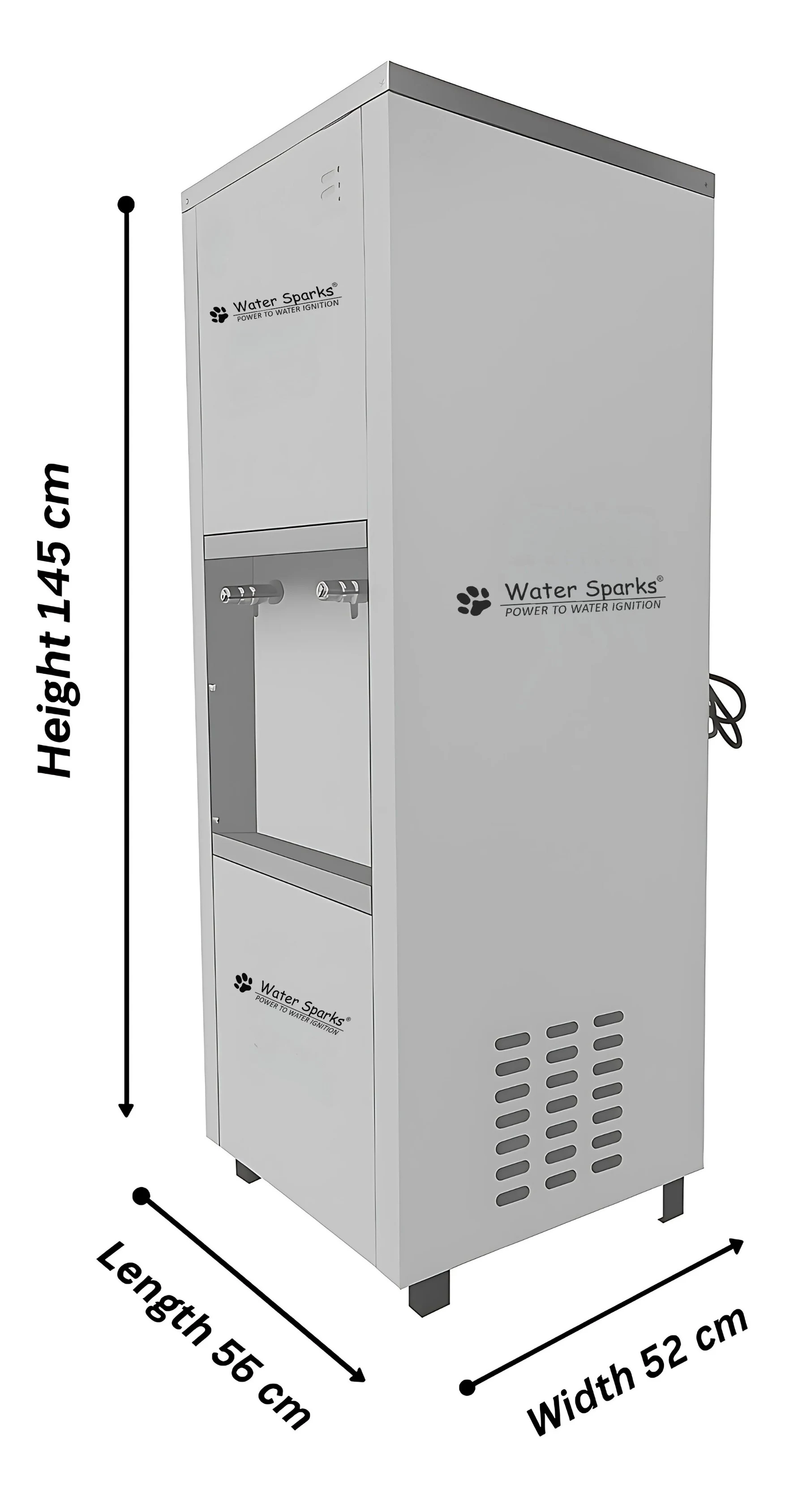

Features of Water Dispenser for Hospitals

- Made in 304 - Stainless Steel Design

- You can Customizable upto 6 taps

- 80 Liters Storage Capacity.

- Compact Model Design

- LED Indicator

- Output - Hot, Cold, & Normal Water

Our Watersparks Happy Family

GOODTrustindex verifies that the original source of the review is Google. Got clarity by hearing the technical briefing by you engineerPosted onTrustindex verifies that the original source of the review is Google. Water sparks have provided apt consultation w.r.t to my water problem. Mr Faarish has very patiently explained the pros and cons. His advice has definitely made us make the right choices. Thank you very much.Posted onTrustindex verifies that the original source of the review is Google. I interacted with the staff member, Mr. Faarish, who provided an excellent response and clear explanation. His service was professional and courteous, and I am really satisfied with the overall experience.Posted onTrustindex verifies that the original source of the review is Google. I had been planning to install water tank filters and approached Mr. Faarish for advice. Instead of rushing into the installation, he recommended conducting a proper water quality report first. Based on the results, it turned out that the filters were not necessary for my specific situation. This guidance saved me a significant amount of money. Mr. Faarish was honest, knowledgeable, and genuinely focused on my best interest rather than just making a sale. I truly appreciate his professional support and integrity. It’s rare to find someone so trustworthy in this field — highly recommended!Posted onTrustindex verifies that the original source of the review is Google. We were already using a water softener system which involves lot of manual work to operate rotate the Knob to wash it with salt and it requires frequent Softener Resine change every year We had to spend atleast 12k and the reason task is to follow up the person to change the media, so we looked into Water Sparks product while we search online and we had installed their Fully Automatic Water Softener Plant and Fully Automatic Filtration System, where the manual work is no more. Only work is we have to add Rock salt every 7 days or 10 days once, the water is better now. And we are never nearing the water plant to do the cleaning work which is really hassle free for us. Definitely we received a good support and post installation we had doubts to cope up with the system and we got a clear explanation for all our queries. Thanks team for your support and patience will recommend the product to my friends and if anybody reading this review have a call with their Experts to have a consultation.

Hospitals RO Plant - Actual Project Installation

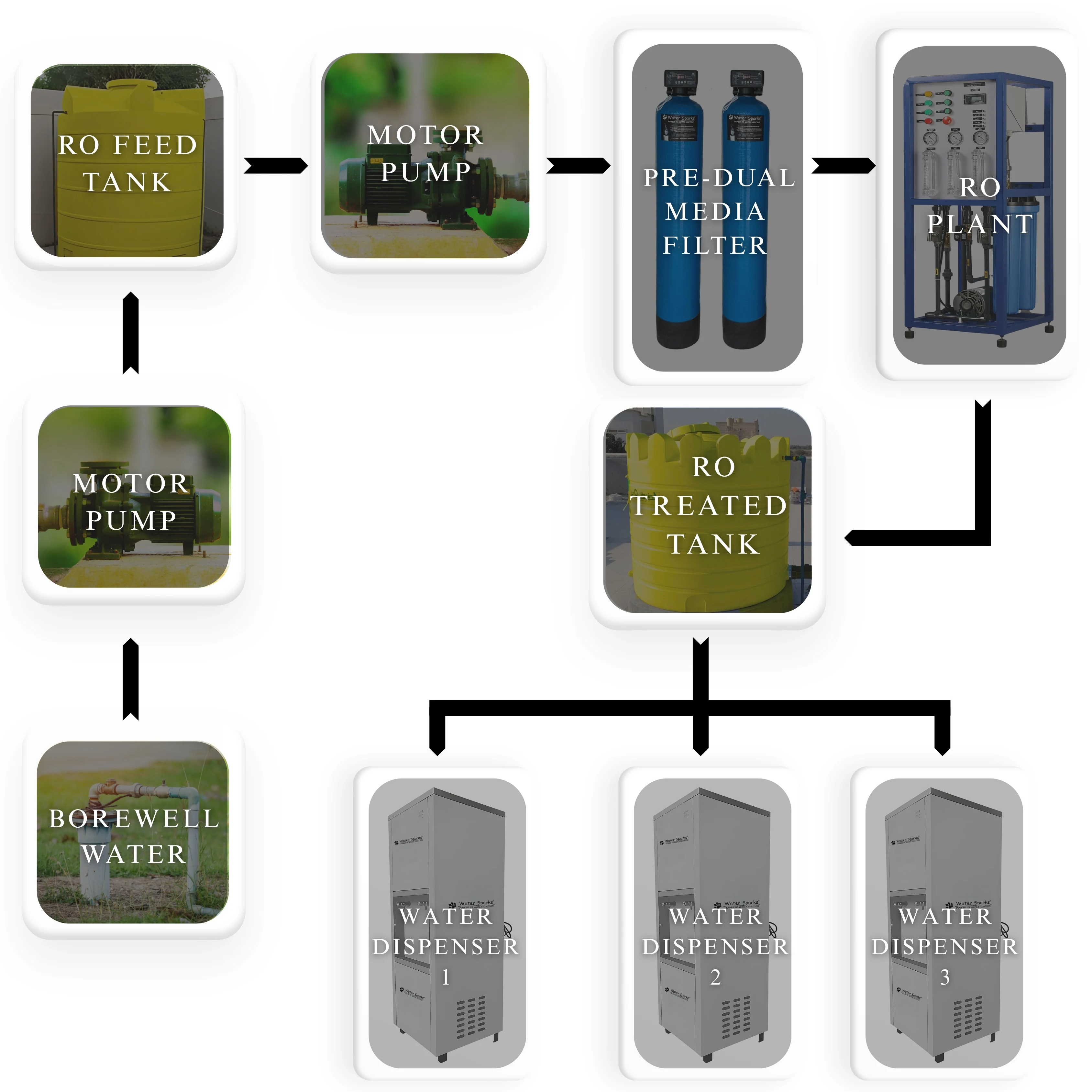

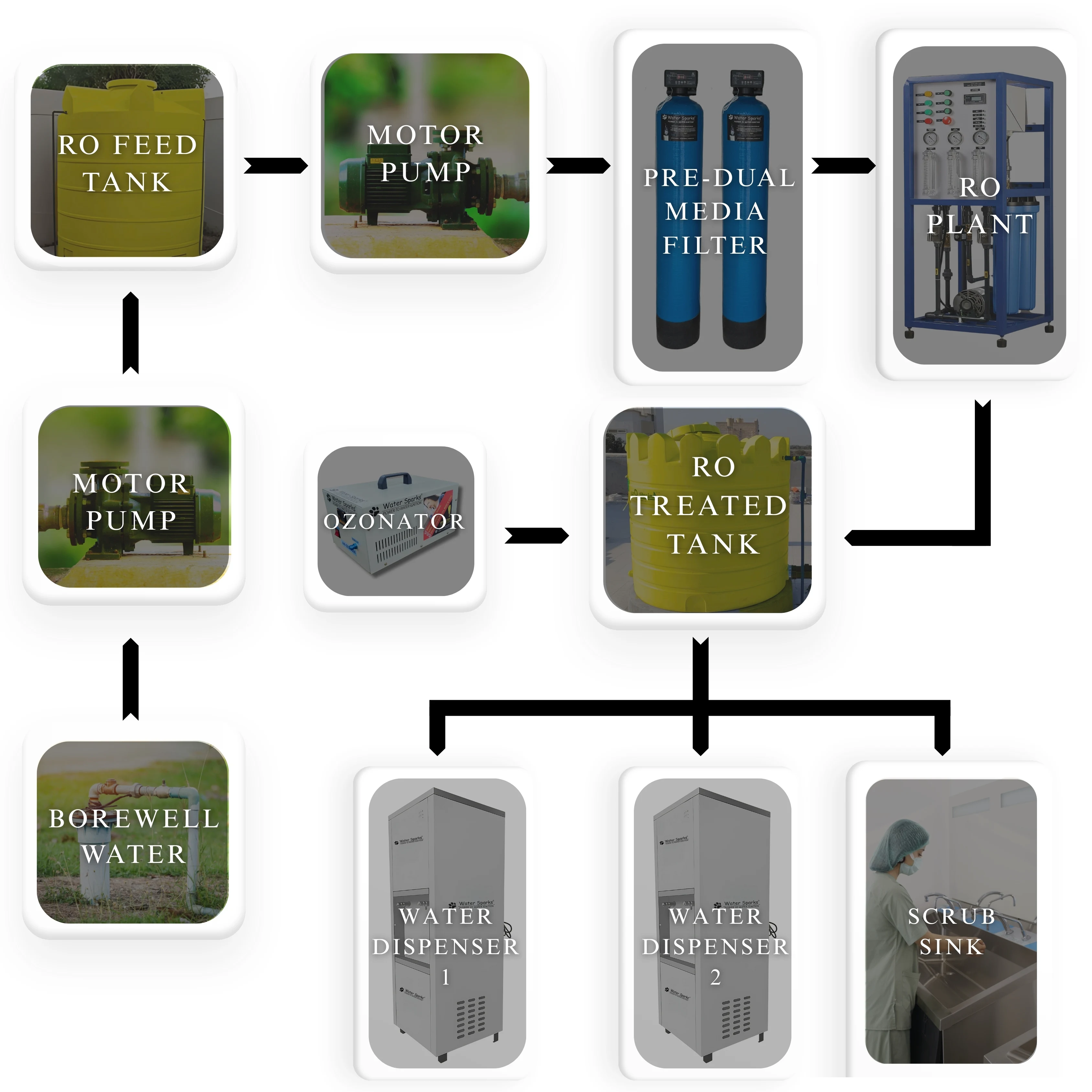

Checklist to install Centralized RO Plant for Drinking Water

- Assess water quality

- Choose the right RO system

- Find installation location

- Gather necessary equipment

- Install pre-filters

- Connect the RO system

- Install post-filters and storage tank

- Connect the drain line

- Check for leaks and test the system

- Maintenance and servicing

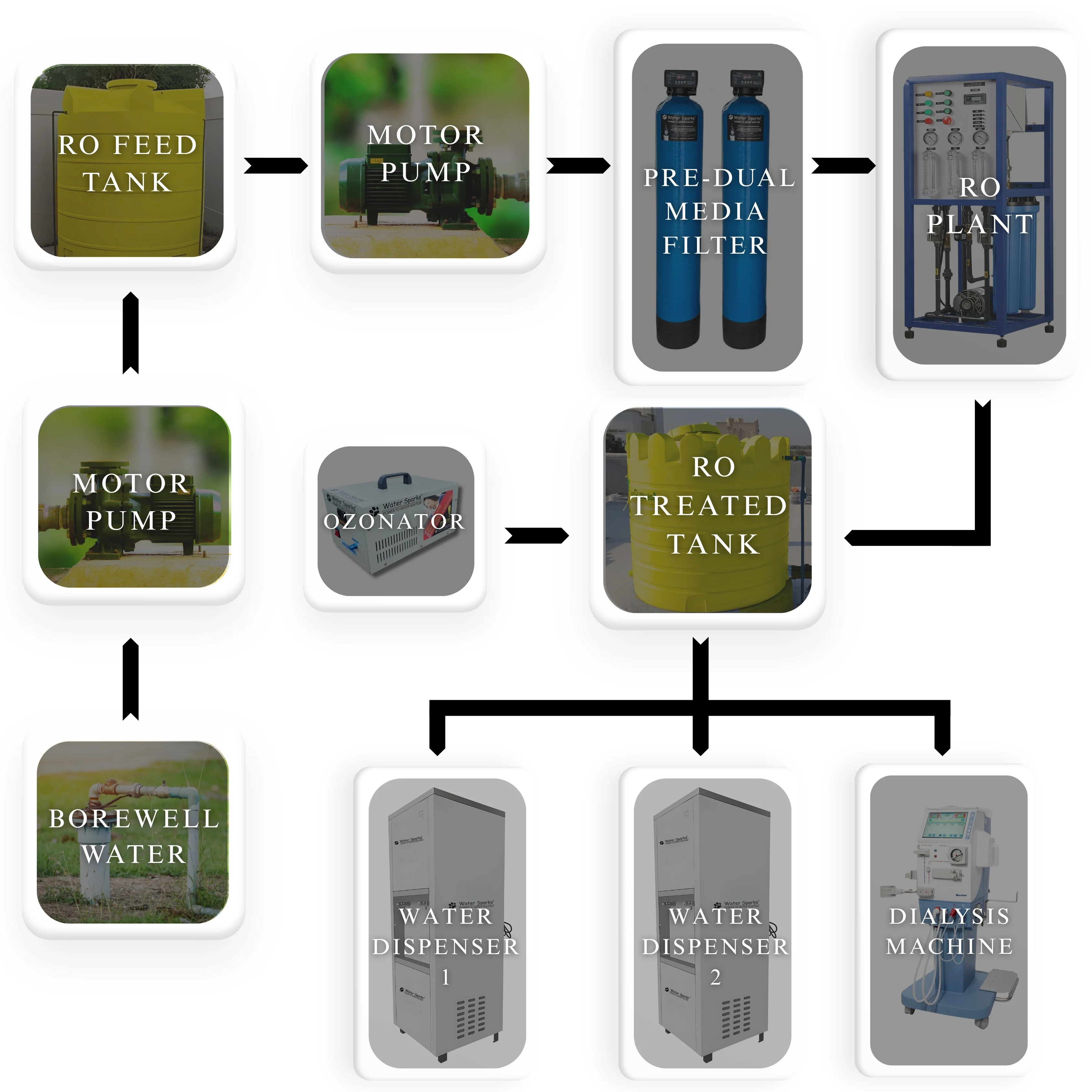

Checklist to install Centralized RO Plant for Dialysis System

- Assess water quality

- Choose the right RO system

- Find installation location

- Gather necessary equipment

- Install pre-filters

- Connect the RO system

- Install post-filters and a storage tank with UV

- Connect the ozanator to the storage tank

- Connect to dialysis

- Connect the drain line

- Check for leaks and test the system

- Maintenance and servicing

- Go for the AMC plan

- Do by monthly water test

Checklist to install Centralized RO Plant for Scrubbing Station

- Assess water quality

- Choose the right RO system

- UV filter

- Ozination system

- Find installation location

- Gather necessary equipment

- Install pre-filters

- Install scrubbing

- Connect the RO system

- Install post-filters and a storage tank with UV

- Connect the ozanator to the storage tank

- Install scrubbing station

- Connect the drain line

- Check for leaks and test the system

- Maintenance and servicing

- Go for the AMC plan

- Do by monthly water test

FAQ - RO Plant For Hospitals

Why do hospitals need an RO plant?

Hospitals require RO plants to ensure the water used for drinking, patient care, laboratory tests, dialysis, and medical equipment cleaning is free from harmful contaminants, high TDS, bacteria, and viruses. Pure water is crucial for patient safety, hygiene, and the proper functioning of medical devices.

What type of RO plant is suitable for hospitals?

The ideal RO plant for hospitals depends on water usage volume, source water quality, and application areas. Most hospitals use commercial or industrial RO plants with multi-stage filtration, UV sterilization, and sometimes UF (Ultrafiltration) to ensure maximum purity.

Can an RO plant be used for hospital dialysis units?

Yes, but dialysis water treatment requires specialized medical-grade RO systems that meet AAMI (Association for the Advancement of Medical Instrumentation) standards. These systems include additional pre-treatment, polishing filters, and endotoxin control.

How much capacity should a hospital RO plant have?

Capacity varies based on hospital size:

Small clinics: 250–500 LPH RO plant

Medium hospitals: 1000–2000 LPH RO plant

Large multispecialty hospitals: 3000 LPH and above

A water audit is recommended to choose the correct size.

Does an RO plant remove bacteria and viruses from hospital water?

Yes. RO membranes remove up to 99% of microorganisms. When combined with UV or UF disinfection, the system ensures complete protection against bacteria, viruses, and cysts.

Can a single RO plant supply pure water for the entire hospital?

Yes. A centralized RO plant can supply pure water to multiple points, such as drinking areas, laboratories, ICUs, and dialysis units. However, some sensitive areas like dialysis may still require an additional dedicated RO system.

Read More

RO Plant In Hospitals & Healthcare

An 1000 LPH RO plant in hospital settings is critical for safe medical operations. The RO plant in hospital facilities helps eliminate harmful substances like heavy metals, bacteria, and salts. An automatic RO system for TDS removal ensures the water used in ICUs and operation theatres is clean and safe. Hospitals now rely on an automatic RO plant with UV and UF for consistent protection. The use of an automatic RO treatment for drinking water in hospitals further supports patient safety and improves staff confidence.

Why an Automatic RO water treatment plant is Critical in Dialysis Units

The 500 LPH RO plant in dialysis unit operations ensures the water used in hemodialysis, nephro dialysis, and kidney dialysis is of the highest quality. Low TDS water for dialysis unit setups prevent complications such as fluid imbalance, chemical reactions, and infections. The purity level achieved through an automatic RO plant for dialysis unit exceeds standard requirements. A compact RO plant for dialysis is ideal for small clinics and mobile healthcare units. These provide salt free water for dialysis unit procedures, reducing patient risk significantly. Using a Dialysis automatic RO plant is now the standard across healthcare networks, as it promotes patient safety and compliance with medical protocols.

Sterile RO Water for Surgical and ICU Applications

Each RO plant in hospital infrastructure supports surgical and ICU procedures. For example, automatic RO water for surgical scrub sink ensures sterile conditions during pre-op and post-op care. Sterile water surgical scrub sink setups minimize infection risk in sensitive zones. These systems also deliver pure water for dialysis unit procedures. Automatic RO plant for dialysis unit usage guarantees consistent, pure water for dialysis unit flow. Modern hospital setups require an automatic RO plant hospitals can rely on for performance and durability across departments.

Role of RO Plants in Hemodialysis, Nephro Dialysis & Kidney Dialysis

Hospital water systems now include automatic RO plant for hemodialysis applications. Automatic RO plant for nephro dialysis supports precision treatments with better control over water quality. Automatic RO plant for kidney dialysis unit setups enable uninterrupted patient care in busy hospital settings. A compact RO plant for dialysis is space-efficient, highly automated, and easy to maintain. The automatic RO plant hospitals need today must include advanced filtering features like UV and UF to ensure effective microbial elimination and chemical balance.

Automatic RO Systems for Drinking Water in Healthcare

Whether for sterilization, patient care, or drinking water, automatic RO treatment for drinking water plays a key role. The RO plant in dialysis unit ensures salt free water for dialysis unit use throughout patient care cycles. With every automatic RO system for TDS removal, hospitals boost safety and eliminate inconsistencies. Hospital engineering teams choose automatic RO plant with UV and UF filters for reliable, long-term operation. These systems ensure the delivery of pure water for dialysis units and all other medical uses.

Meeting Growing Demands Through Compact and Scalable RO Solutions

An automatic RO plant for dialysis unit also contributes to better patient outcomes, especially during continuous or emergency dialysis procedures. RO plant in hospital design now includes compact RO plant for dialysis setups to meet diverse facility sizes and layouts. Hospitals requiring sterile water surgical scrub sink solutions trust an automatic RO water for surgical scrub sink system to comply with hygiene protocols. As healthcare water demands grow, so does the need for salt free water for dialysis unit technology with seamless scalability. The automatic RO plant hospitals use must meet these evolving needs while maintaining optimal efficiency.

How Does an Automatic RO Plant Work?

An 1000 LPH RO plant, or reverse osmosis system, purifies water through a multi-stage process designed to remove dissolved salts, harmful contaminants, and impurities. At the heart of the system is a semi-permeable membrane that cleans the water molecules before passing, blocking things like bacteria, viruses, chemicals, and heavy metals. [1]

The process starts with pre-treatment, where water goes through filters to remove dirt, sand, and chlorine—this protects the RO membrane. Then, a high-pressure pump pushes the water through the membrane. The clean water that comes out is called permeate, and the leftover water containing all the rejected salts and impurities is called brine or reject water.

Our automatic RO plants also has a post-treatment stage, using UV sterilizers or UF (ultrafiltration) units to kill any remaining microbes and improve taste and odor. In some cases, remineralization is added to balance the water for drinking. These stages make an automatic RO system for TDS removal a vital part of any hospital.

In hospitals, especially in dialysis units, this process is crucial for producing low TDS, salt-free, and medical-grade RO water needed for hemodialysis, nephro dialysis, and use at the surgical scrub sink, where sterile water is essential. This means a hospital cannot compromise on the quality of the RO plant in hospital settings.

Whether for drinking water, kidney dialysis, or compact RO plants for hospitals, the goal of these automatic RO systems is always the same: to provide pure, safe, and reliable water with minimal manual intervention. Today, advanced hospital RO plant manufacturing ensures these systems run efficiently and meet strict medical standards. The increasing demand for automatic RO plant hospitals highlights the importance of reliable water infrastructure.

Automatic RO plant solutions are now considered standard in any modern dialysis unit, as they help maintain consistent, low TDS water essential for safe treatment. Hospital RO plant manufacturing continues to innovate, offering compact RO plant options for space-limited setups without compromising on water quality. In each dialysis unit, using a reliable, automatic RO plant helps achieve salt-free water with the purity required for medical-grade RO water preparation. Medical-grade RO water must meet specific parameters that only an advanced automatic RO plant can consistently deliver. The presence of a 1000 LPH RO plant in dialysis unit environments is not just preferred—it’s critical.

A compact RO plant is also highly beneficial in small clinics and mobile dialysis unit setups where full-scale systems may not be feasible. Leading hospital RO plant manufacturing companies now design compact RO plant systems that are plug-and-play, offering low TDS and salt-free water output from day one. Whether it’s for a large dialysis unit or a smaller setup, having an automatic RO plant that delivers medical-grade RO water ensures both compliance and patient safety. [2]

The future of hospital RO plant manufacturing lies in efficiency, safety, and adaptability—making sure every dialysis unit has the tools it needs to function without risk. Additionally, an automatic RO treatment for drinking water is now a necessity in most hospitals, supplying clean, palatable water for patients and staff. It’s not only the dialysis department that benefits; an 500 LPH RO plant in hospital facilities extends water safety to labs, surgical suites, and more.

Why is an Automatic RO plant important for hospitals?

An RO (Reverse Osmosis) plant is essential for hospitals because it supplies clean, medical-grade water needed for various critical applications. In healthcare settings, where hygiene, safety, and precision are vital, having an automatic RO plant ensures that water is consistently purified and free from harmful substances. This becomes more important when an 500 LPH RO plant in hospital facilities is tasked with meeting multiple needs simultaneously.

One of the most important uses is in dialysis units. Patients undergoing hemodialysis or nephro dialysis require low TDS, salt-free water, as even small amounts of impurities can be dangerous. An automatic RO plant for dialysis units helps protect patients by delivering pure, sterile water directly to dialysis machines. The reliability of an automatic RO system for TDS removal plays a direct role in the success of patient treatment. RO water is also used in surgical areas—for cleaning instruments, surgical scrub sinks, and wounds—where sterile water is required to reduce the risk of infections.

In addition, laboratories rely on RO water for preparing solutions, running tests, and sterilizing tools. Automatic RO systems with UV and UF filtration add another layer of safety by eliminating bacteria and viruses. This is why an automatic RO plant with UV and UF has become a staple in hospital infrastructure. A compact RO plant for dialysis or an automatic RO water treatment plant for hospital-wide use also supports autoclaves and other sterilization equipment, ensuring medical tools are properly disinfected.

Installing an automatic RO plant in every dialysis unit ensures that low TDS and salt-free water are consistently available for critical procedures. Having an 1000 LPH RO plant in dialysis unit departments reinforces the quality and safety of all treatments. As compact RO plant models become more advanced, even small-scale dialysis unit setups can benefit from medical-grade RO water without sacrificing space or quality.

Hospital RO plant manufacturing continues to evolve, offering automatic RO plant designs tailored to deliver salt-free, medical-grade RO water at every point of use. This includes compact RO plant systems designed to efficiently serve remote or rural hospitals. Whether it’s a compact RO plant for dialysis in a mobile unit or a centralized setup for the entire hospital, the delivery of low TDS water is essential to meet strict medical standards.

This not only ensures patient safety but also helps healthcare facilities stay fully compliant with necessary regulations. Hospitals are also choosing automatic RO water for surgical scrub sink installations that ensure zero contamination risks. Having sterile water surgical scrub sink infrastructure is no longer optional. In fact, many hospitals now opt for multiple compact RO plant installations to guarantee localized supply of low TDS, medical-grade RO water in every dialysis unit and ICU.

The automatic RO plant not only supports treatment quality but also ensures infection control through consistent delivery of salt-free, sterile water. Modern hospital RO plant manufacturing ensures that both large hospitals and smaller specialty centers have access to efficient, automatic RO plant systems that prioritize patient safety, low TDS levels, and operational ease. With growing emphasis on water safety, an automatic RO treatment for drinking water is also integrated hospital-wide. [3]

Automatic RO treatment for drinking water also plays a critical role in ensuring hospital staff, patients, and relatives have access to clean and safe hydration. Many automatic RO plant hospitals now include dedicated pipelines for automatic RO treatment for drinking water to improve convenience and safety. This setup supports better overall health outcomes and hospital-wide sanitation efforts.

To further enhance water safety, the automatic RO system for TDS removal is optimized in many modern hospital installations to handle variable water sources. Whether it’s borewell water or municipal supply, the automatic RO system for TDS removal ensures uniform output quality. It also improves the lifespan of medical devices and dialysis systems by maintaining balanced water chemistry.

The automatic RO plant with UV and UF now includes automated monitoring systems, which alert technicians if water quality drops. This makes the automatic RO plant with UV and UF a reliable solution for round-the-clock hospital operations. By integrating an automatic RO plant with UV and UF into daily medical procedures, hospitals can maintain unmatched hygiene standards.

The deployment of automatic RO plant hospitals infrastructure also means faster emergency response capabilities, especially in critical wards. Investing in scalable automatic RO plant hospitals technology ensures long-term cost savings and operational readiness. Today, hospitals are increasingly specifying automatic RO water for surgical scrub sink applications in their engineering plans. Using automatic RO water for surgical scrub sink systems provides sterile rinse water that prevents pathogen transfer. The implementation of automatic RO water for surgical scrub sink infrastructure is now aligned with global healthcare safety guidelines.

Sterile water surgical scrub sink zones now demand more reliable systems. Hospitals have started using sterile water surgical scrub sink units that work seamlessly with the centralized RO plant. These sterile water surgical scrub sink systems protect patients during surgery and medical staff throughout the day. The demand for low TDS water for dialysis unit procedures is higher than ever. To address this, hospitals are deploying dual-stage filtration units dedicated to producing low TDS water for dialysis unit operations. Medical experts now recognize low TDS water for dialysis unit performance as essential to modern treatment protocols.

Delivering pure water for dialysis unit therapy is a high priority. Facilities install advanced sensors and testing protocols to ensure every drop of pure water for dialysis unit use meets safety benchmarks. Whether automated or manual, every hospital must supply pure water for dialysis unit treatments with total accuracy. The Dialysis automatic RO plant has evolved to include cloud-based control features for efficiency tracking. Every Dialysis automatic RO plant now has built-in redundancy to ensure water quality is never compromised. Investing in a Dialysis automatic RO plant gives hospitals greater flexibility during maintenance or emergency scenarios.

The use of an Automatic RO plant for hemodialysis has reduced cross-contamination cases significantly. Many hospitals use an Automatic RO plant for hemodialysis to isolate water supply per patient zone. The Automatic RO plant for hemodialysis is now an integral component of nephrology departments. [4]

Hospitals with growing kidney care units invest in an Automatic RO plant for nephro dialysis to ensure continuous treatment support. The Automatic RO plant for nephro dialysis provides uninterrupted, bacteria-free water tailored to clinical needs. Emergency dialysis setups often rely on a mobile Automatic RO plant for nephro dialysis for on-the-go care.

An Automatic RO plant for kidney dialysis unit supports peak patient loads with consistent water output. Centralized Automatic RO plant for kidney dialysis unit systems are now paired with backup generators to ensure no downtime. The use of Automatic RO plant for kidney dialysis unit operations reduces operational costs and boosts reliability. Salt free water for dialysis unit treatment is essential for reducing inflammation and toxin buildup. Engineers now design systems that guarantee salt free water for dialysis unit usage 24/7. Without salt free water for dialysis unit support, modern dialysis would face considerable health risks.

How does an Automatic RO plant help in dialysis

An RO plant, or reverse osmosis system, is essential in dialysis because it provides clean, safe water required for treatment. In a dialysis unit, purified water is mixed with chemicals to create a fluid called dialysate, which interacts with the patient’s blood through a semi-permeable membrane. If the water contains impurities like bacteria, viruses, chlorine, heavy metals, or endotoxins, it can lead to serious health problems such as infections, fever, inflammation, or hemolysis. Therefore, the role of the RO plant in dialysis unit operations is pivotal.

An automatic RO plant for dialysis units helps eliminate up to 98% of these harmful substances. These systems often include multiple stages of filtration—such as sediment filters, carbon filters, UV, and UF—to ensure water is consistently purified. This type of medical-grade RO plant is especially important in hospitals where hemodialysis, nephro dialysis, or kidney dialysis treatments are performed. Hospitals depend on the performance of every automatic RO plant for kidney dialysis unit applications.

RO systems are also designed to supply low TDS, salt-free water that meets strict medical safety standards. Compact RO plants are ideal for smaller dialysis units, offering efficient water purification without taking up too much space. On the other hand, fully automatic RO water treatment plants are designed to handle the demands of larger hospital operations. These systems are especially important in delivering sterile water for surgical scrub sinks and other high-risk zones. By integrating automatic RO water for surgical scrub sink setups, hospitals can significantly improve hygiene and reduce the risk of contamination.

Today, hospital RO plant manufacturing is all about creating dependable and user-friendly systems that consistently deliver pure water and support patient safety. In any healthcare setting, especially in a dialysis unit, having a proper RO plant in dialysis unit isn’t optional—it’s essential. Without it, treatments become risky and unpredictable. That’s why installing a Dialysis automatic RO plant has become a standard—it significantly reduces contamination risks, thus improving patients’ outcomes.

Each automatic RO plant is specially designed to meet the needs of a dialysis unit by consistently delivering low TDS, salt-free water for safe patient use. In many hospitals, a compact RO plant is used to support individual dialysis units, especially where space is limited but demand for medical-grade RO water is high.

Whether for a large or small healthcare center, hospital RO plant manufacturing is centered around creating automatic RO plant solutions that offer long-term performance and reliability.

The key to safe dialysis lies in ensuring that every dialysis unit has access to automatic RO plant technology that produces consistent, sterile, and medical-grade RO water. Additionally, compact RO plant designs make it easier for clinics and small-scale dialysis units to maintain the same water quality standards as larger facilities. As the number of dialysis procedures increases, the need for a 500 LPH RO plant in hospital and dialysis environments becomes even more critical.

With the growing demand for low TDS and salt-free water across all medical departments, hospital RO plant manufacturing now integrates features like remote monitoring and energy-efficient filtration in every automatic RO plant. By delivering high-purity, medical-grade RO water through compact RO plant units or full-scale systems, healthcare providers can ensure both treatment success and operational efficiency in every dialysis unit. Whether it’s a dialysis automatic RO plant or an automatic RO plant for hemodialysis, consistency in water quality must never be compromised.

Benefits of Having an Automatic RO system for TDS removal in Hospitals

Having a 1000 LPH RO plant in hospitals is not just about clean water—it’s about ensuring safe medical care, protecting equipment, and supporting daily operations in critical environments like dialysis units and surgical wards. With advancements in automatic RO systems, hospitals can now maintain consistent water quality with minimal intervention.

Safe Dialysis Treatment

An RO plant in the dialysis unit provides low TDS, salt-free water essential for hemodialysis and nephro dialysis. It protects patients from life-threatening contaminants like bacteria, heavy metals, and chlorine. Automatic RO plant installations in each dialysis unit enhance safety by ensuring water remains within clinical thresholds. Delivering medical-grade RO water to every dialysis unit ensures the treatment process stays uncompromised. Consistently supplying low TDS, salt-free water helps prevent complications during extended dialysis sessions.

Sterile Water for Surgical Use

Automatic RO water systems supply sterile water to surgical scrub sinks, helping reduce infection risks during operations and post-surgery care. Medical-grade RO water is crucial in surgical zones, especially where sterilization is required before and after procedures. An automatic RO plant ensures that low TDS water is available at the point of use during critical surgical applications. Many hospitals integrate compact RO plant units near operating rooms for direct access to clean, salt-free water.

Compact and Space-Saving Design

A compact RO plant for dialysis or smaller hospital setups saves space without compromising performance, making it ideal for urban or limited-space healthcare centers. Compact RO plant solutions are also easier to install and maintain, especially in small-scale dialysis units. Even with limited infrastructure, a compact RO plant delivers the same high-quality, medical-grade RO water required for patient safety. Hospitals seeking modular water solutions often choose compact RO plant models developed through specialized hospital RO plant manufacturing.

Consistent Water Quality with Automation

An automatic RO plant with UV and UF filtration provides round-the-clock water purification, ensuring consistent safety standards across departments. Whether installed in a dialysis unit or near a surgical scrub sink, the automatic RO plant delivers low TDS, salt-free water without the need for constant monitoring. Medical-grade RO water output is guaranteed across shifts, thanks to automation. Hospital RO plant manufacturing now focuses heavily on integrating smart features into every automatic RO plant for better control and traceability.

Improved Equipment Lifespan

Using purified RO water reduces mineral buildup in autoclaves and other medical equipment, lowering maintenance costs and preventing breakdowns. Salt-free, low TDS water extends the life of expensive machines used in dialysis units and surgical rooms. Automatic RO plant systems also help preserve the integrity of sterilization tools and lab instruments. The use of medical-grade RO water protects internal surfaces from corrosion and mineral fouling.

Compliance with Medical Standards

Medical-grade RO plants are designed to meet strict water quality standards required for dialysis and surgical applications, supporting hospital accreditation and compliance. Every dialysis unit must rely on water that meets low TDS and salt-free criteria to ensure treatment safety. Compact RO plant designs are often pre-certified to align with hospital RO plant manufacturing norms. Regular audits are easily passed when hospitals use automatic RO plant setups verified for medical-grade RO water delivery.

Versatile Applications Across the Hospital

RO water is used in labs, ICUs, sterilization units, and for drinking—making it a central utility for multiple hospital functions. Whether it’s a dialysis unit or an emergency operating ward, an automatic RO plant ensures reliable access to salt-free water. Hospitals deploy compact RO plant units in decentralized departments for flexible water distribution. Medical-grade RO water supports laboratory testing accuracy, patient hydration, and sterile cleaning processes.

Reduces Risk of Waterborne Infections

With multi-stage purification, RO systems remove harmful pathogens and endotoxins, protecting vulnerable patients from water-related infections. In dialysis units, this is especially critical, as exposure to unsafe water can be fatal. Hospital RO plant manufacturing incorporates multiple disinfection methods into every automatic RO plant to meet infection control protocols. Whether through compact RO plant modules or centralized systems, low TDS, salt-free, medical-grade RO water significantly reduces microbial risk.

Supports Emergency Readiness

In emergency or critical care scenarios, a reliable automatic RO water treatment plant ensures uninterrupted supply of safe water, which is vital for treatment continuity. Every dialysis unit must remain operational during emergencies, which is why a backup automatic RO plant is often recommended. Compact RO plant units offer flexible deployment in temporary or mobile medical units. Hospital RO plant manufacturing increasingly emphasizes quick-installation and rapid-response designs to support such needs.

Backed by Specialized Manufacturing

Hospital RO plant manufacturing focuses on durability, compliance, and efficiency—ensuring these systems meet the daily demands of healthcare environments. Each automatic RO plant is engineered to provide consistent, medical-grade RO water to every dialysis unit and critical care area. Manufacturers now offer compact RO plant options that can be customized based on hospital layout and usage. These systems are built to consistently deliver low TDS, salt-free water while complying with the latest medical standards.

Health Risks Caused by High TDS in Water

High Total Dissolved Solids (TDS) in water can lead to serious health concerns, particularly in sensitive settings like hospitals and dialysis units. In medical-grade applications, water with high TDS often carries harmful contaminants like heavy metals, salts, and bacteria, making it unsafe for patient care and critical medical procedures.For patients undergoing treatments like hemodialysis or nephro dialysis, exposure to high TDS water can lead to complications such as fluid imbalance, hypertension, inflammation, and even hemolysis (destruction of red blood cells). In dialysis units, the absence of an automatic RO plant to remove TDS and other impurities increases the risk of infections and organ stress.

For surgical procedures, using non-sterile or high TDS water at surgical scrub sinks can compromise hygiene and increase the chances of post-operative infections. That’s why hospital RO plant manufacturing focuses on automatic RO systems that provide low TDS, salt-free, and sterile water for safe use in kidney dialysis, surgical cleaning, and medical device sterilization.

An automatic RO plant is vital in preventing exposure to unsafe water conditions during kidney dialysis procedures. These systems are built to produce salt-free water that ensures the safety of dialysis patients. The automatic RO plant also supports other hospital processes that require sterile, low TDS water such as in surgical scrub sink stations and sterilization equipment.

Medical-grade RO plant installations are now standard in modern hospitals due to the increasing demand for high-quality water. These systems are especially common in dialysis units, surgical wings, and ICUs. Hospital RO plant manufacturing today is focused on compact, automatic RO plant designs that can deliver consistent low TDS water around the clock. Advanced manufacturing also ensures that each hospital RO plant is built for longevity, regulatory compliance, and uninterrupted performance.

To support growing healthcare needs, hospital RO plant manufacturing emphasizes reliability and efficiency across multiple use cases, including kidney dialysis and surgical scrub sink hygiene. The combined impact of automatic RO plant technology and salt-free water production integration helps hospitals maintain the highest standards in patient safety.

How Automatic RO Plant Installation in Hospitals Reduces Health Risks

Installing an automatic RO plant in hospitals is one of the most effective ways to reduce health risks associated with contaminated or high TDS water. RO systems help eliminate harmful substances such as heavy metals, dissolved salts, bacteria, viruses, and endotoxins that pose a threat to patient safety. In dialysis units, an RO plant ensures that only low TDS, salt-free, and medical-grade water is used for treatments like hemodialysis and nephro dialysis, significantly lowering the risk of infection, inflammation, and blood-related complications.

Sterile water supplied through an RO system is also essential at surgical scrub sinks and in ICU procedures, where hygiene is critical. Automatic RO plants with UV and UF further strengthen protection by destroying microorganisms and improving water quality across all departments. With compact RO plants available for dialysis and specialized hospital RO plant manufacturing, healthcare facilities can ensure safer treatments, cleaner environments, and overall better outcomes for patients.

An automatic RO plant plays a crucial role in every stage of kidney dialysis, from dialysate preparation to machine sterilization. These systems are engineered to consistently deliver low TDS, salt-free water without manual intervention. Whether used in a large hospital or a mobile dialysis unit, the presence of an automatic RO plant ensures uninterrupted supply of medical-grade RO water.Using salt-free water is not only critical for kidney dialysis but also for sterilizing tools and cleaning areas like the surgical scrub sink. A medical-grade RO plant ensures that the water quality meets the standards required for direct patient contact and high-precision medical care.

Modern hospital RO plant manufacturing now focuses on compact, energy-efficient systems that are easier to install and maintain. These manufacturers design every automatic RO plant to meet the demanding water purity levels necessary in surgical scrub sink areas, dialysis units, and intensive care. From supporting kidney dialysis to providing low TDS water in operating rooms, Automatic RO plant for nephro dialysis solutions have become a core element of hospital infrastructure. Hospital RO plant manufacturing is aligned with healthcare regulations, ensuring every system can reliably supply salt-free water to sensitive departments.

Why Water Sparks Is the Best Choice for RO plant in hospital in Chennai, Coimbatore, Bangalore, and Hyderabad

Expertise in Medical-Grade Systems : Specializes in hospital RO plant manufacturing designed for healthcare environments. Offers automatic RO plants built to meet strict medical and hygiene standards. Every medical-grade RO plant is engineered to deliver consistently safe water for hospitals. Hospital RO plant manufacturing follows stringent protocols to support infection-free medical processes.

Ideal for Dialysis Applications: Provides reliable RO plants for dialysis units, including hemodialysis, nephro dialysis, and kidney dialysis. Ensures safe, low TDS, and salt-free water to protect patients during treatment. An automatic RO plant ensures the continuous supply of purified water needed for kidney dialysis. Low TDS and salt-free water are crucial to preventing complications in dialysis patients.

Support for Surgical and ICU Needs: Supplies sterile water for surgical scrub sinks, wound cleaning, and critical care procedures. Reduces infection risks in sensitive hospital zones through high-purity water. A medical-grade RO plant ensures the water used at each surgical scrub sink meets hygiene standards. Automatic RO plant systems maintain uninterrupted flow of sterile water for ICU use.

Advanced Multi-Stage Filtration: Systems include UV and UF filters to remove bacteria, viruses, and dissolved contaminants. Delivers consistent water quality across all departments in the hospital. Salt-free water helps improve the efficiency of UV and UF filtration stages. Each stage in a medical-grade RO plant is designed for maximum contaminant removal.

Space-Efficient and Automated Solutions: Offers compact RO plants suitable for limited-space hospital setups. Fully automatic RO water treatment plants reduce manual effort and human error. Automatic RO plant designs focus on minimal space usage with full operational control. Compact systems still deliver the required low TDS and sterile output for medical use.

Protects Equipment and Ensures Longevity: Purified water helps prevent scaling and corrosion in autoclaves and other medical devices. Lowers maintenance costs and extends equipment life. Salt-free water prevents buildup that can damage sterilization units. Using a hospital-grade automatic RO plant extends the reliability of sensitive hospital tools.

Trusted Partner in Healthcare: Known for reliability, efficiency, and long-term support in the medical industry. Water Sparks is the preferred choice when hospitals need dependable, medical-grade RO systems. The company leads in hospital RO plant manufacturing with a focus on innovation and safety.Hospitals trust Water Sparks for consistent low TDS, medical-grade water across all departments.

Water Sparks RO Plant for Hospitals – Serving Chennai, Coimbatore, Bengaluru, and Hyderabad

Water Sparks is your trusted partner for automatic RO plants designed specifically for hospitals, dialysis units, and surgical areas. If you’re facing any of the following challenges, it’s time to upgrade to a reliable, medical-grade RO system:

- Is your hospital still depending on manual or outdated water treatment systems that compromise hygiene and safety?

- Are you experiencing recurring scale buildup or TDS issues that affect your dialysis unit or sterilization equipment?

- Do you need a compact RO plant for dialysis that fits into tight spaces without sacrificing performance?

- Have past RO system installations or online purchases failed to meet required medical water quality standards?

Our automatic RO water treatment plants are built with precision, featuring UV, UF, and multi-stage filtration to deliver low TDS, salt-free, and sterile water—perfect for nephro dialysis, surgical scrub sinks, and ICUs.

Improve Your Hospital’s Water Quality with Water Sparks

If your hospital is facing challenges like high TDS, bacterial contamination, or inconsistent water purity, it’s time to act. Water quality directly affects patient care, dialysis safety, surgical hygiene, and medical equipment performance. Protect your facility with a trusted water purification system.

- Request a site visit today and let Water Sparks assess your hospital’s water quality needs.

- Install Water Sparks’ advanced automatic RO plant for hospitals and ensure a consistent supply of pure, sterile, and medical-grade water.

- Choose from fully automatic RO systems with UV and UF, compact RO plants for dialysis, or large-scale hospital RO plant setups.

- Provide safe water for your dialysis unit, surgical scrub sinks, ICU, and sterilization units with Water Sparks’ proven solutions.

Ready to upgrade your water system? Contact us today for a free consultation or a custom quote. We serve hospitals and dialysis units in Chennai, Coimbatore, Bengaluru, and Hyderabad. Our expert team will recommend the right automatic RO plant—whether it’s for hemodialysis, nephro dialysis, or sterile water requirements in critical care units. Trust Water Sparks to deliver low TDS, salt-free, and sterile water with our hospital-grade RO plants. Ensure hygiene, protect your patients, and meet medical water standards with confidence. Contact our healthcare water expert now.