Chlorine Dosing System with Iron Removal Plant

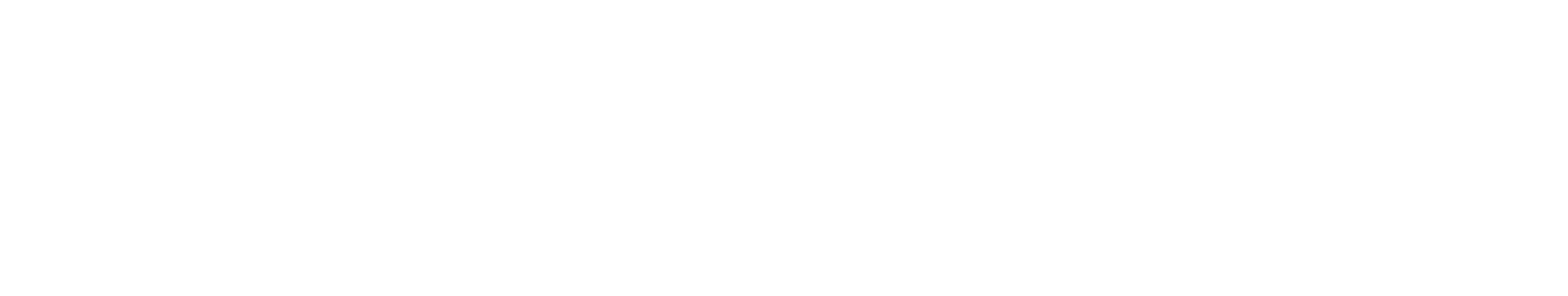

The combination of an iron removal plant and a chlorine dosing system may be required in certain water treatment scenarios to address specific water quality issues and to remove high levels of iron.

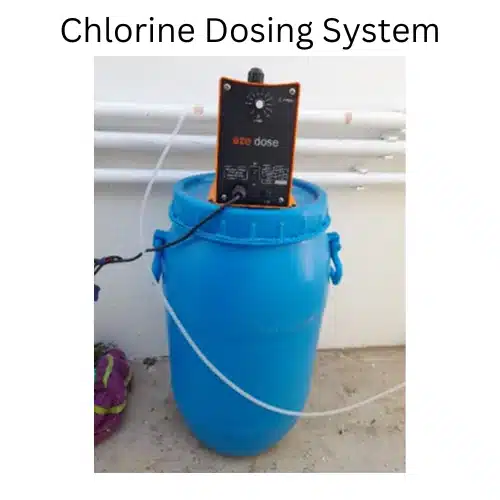

In some places, the concentration of iron in water can exceed 3 ppm (parts per million) due to various reasons. These reasons can include natural geological conditions, such as the presence of iron-rich minerals or rocks in the water source. Additionally, human activities like mining, industrial discharges, or corrosion of iron-containing infrastructure can contribute to elevated iron levels in water. Factors such as groundwater contamination, soil erosion, or agricultural practices may also influence the iron concentration.

When iron levels exceed 3 ppm, it becomes more challenging to effectively remove iron through typical aeration and settling processes. Higher iron concentrations can require additional treatment methods, such as enhanced aeration systems, pH adjustment, or specialized filtration techniques like media filtration or activated carbon filters. It is important to implement appropriate water treatment strategies and consult with water treatment professionals to address specific iron removal challenges based on the local water characteristics and iron concentration levels.

Adding chlorine dosing prior to the aeration process can enhance the settlement of iron in water. Chlorine, being a powerful oxidizing agent, facilitates the conversion of soluble ferrous iron (Fe²⁺) into insoluble ferric iron (Fe³⁺). This oxidation step is crucial for the subsequent settling process. Additionally, chlorine promotes coagulation by destabilizing and aggregating iron particles, leading to the formation of larger, denser particles that are more prone to settling. Furthermore, chlorine dosing aids in the removal of organic matter, which can interfere with iron settlement by forming complex compounds. By oxidizing and breaking down organic compounds, chlorine reduces their interference, allowing iron particles to settle more effectively. This combination of oxidation, coagulation, and organic matter removal assists in improving iron removal efficiency. Proper assessment and optimization of chlorine dosing and aeration processes by water treatment professionals are essential to achieve optimal iron settlement.

Iron Removal Plant

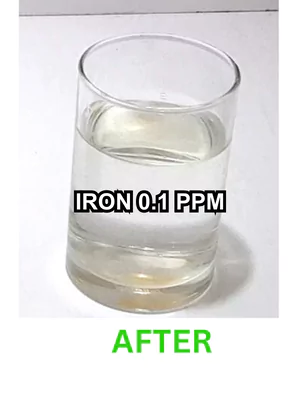

Iron Removal Plant: An iron removal plant is designed to reduce the concentration of iron and other metals in water sources. It is commonly employed in areas where groundwater contains high levels of iron, which can cause aesthetic issues such as discoloration and staining of fixtures, as well as potential health concerns. The plant typically consists of the following components:

- Chlorine Dosing System: A chlorine dosing system is employed to disinfect water and prevent the growth of harmful microorganisms. Chlorine is commonly used as a disinfectant due to its effectiveness and residual disinfection properties. The dosing system typically includes the following components:

- Oxidation: Iron in water exists in two forms—ferrous (soluble) and ferric (insoluble). Oxidation converts the ferrous iron to ferric iron, which can then be effectively removed. Oxidizing agents like chlorine, potassium permanganate, or ozone are commonly used for this purpose.

- Filtration: The oxidized iron is filtered through a media bed, such as sand, manganese dioxide, or granular activated carbon, which traps the insoluble iron particles.

- Backwashing: Periodically, the filter media needs to be cleaned through backwashing, where water is passed through the media in the reverse direction to flush out accumulated iron particles.

- Disinfection: After the iron removal process, the water may undergo disinfection to eliminate any remaining bacteria or pathogens. This is where the chlorine dosing system comes into play.

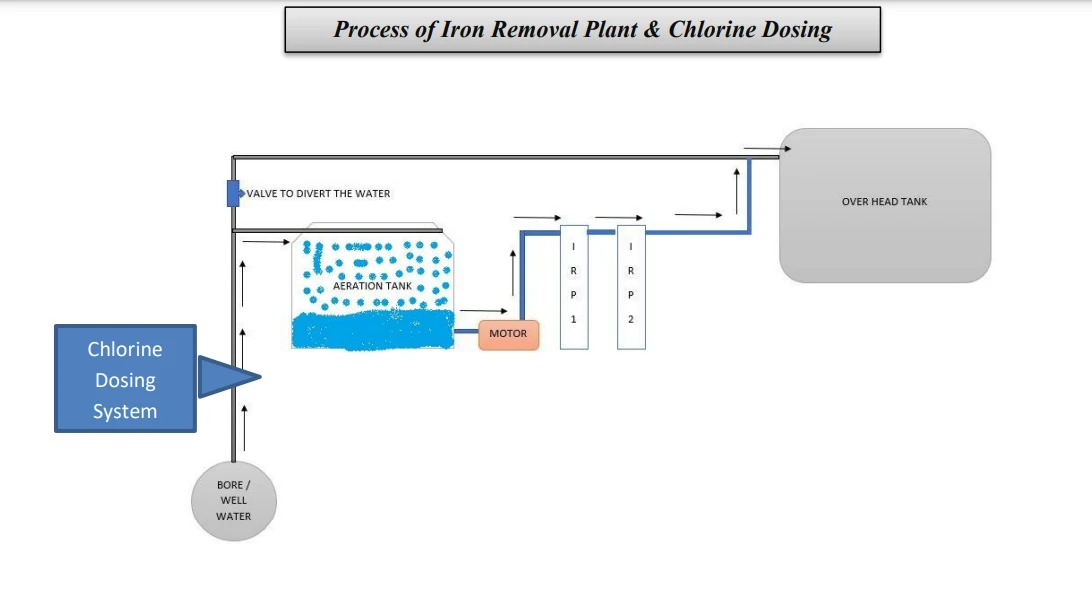

- Chlorine Dosing System: A chlorine dosing system is employed to disinfect water and prevent the growth of harmful microorganisms. Chlorine is commonly used as a disinfectant due to its effectiveness and residual disinfection properties. The dosing system typically includes the following components:

- Chlorine Source: The system consists of a chlorine source, such as liquid chlorine (sodium hypochlorite) or chlorine gas.

- Dosing Equipment: Dosing equipment like chemical feed pumps or chlorine gas feeders is used to introduce the chlorine into the water at a controlled and precise dosage.

- Contact Tank: A contact tank is often included after the dosing point, allowing sufficient contact time for the chlorine to react with any remaining bacteria or pathogens in the water.

- Residual Monitoring: To ensure effective disinfection, residual chlorine levels are monitored using chlorine analyzers or test kits. This helps maintain an appropriate chlorine concentration throughout the water distribution system.