Why is water quality for construction critical in Chennai?

In places like Chennai, water quality for construction directly affects concrete strength, cement hydration, plaster bonding, and long-term durability of structures. Poor-quality water can:

- Reduce compressive strength by up to 15–30%

- Cause cracks, honeycombing, and surface defects.

- Accelerate steel corrosion due to chloride.s

- Promote expansion and cracking from sulphate.

In coastal cities or regions with high groundwater salinity, borewell and tanker water often contain High TDS, hardness, and suspended solids. This makes water testing and treatment essential for safe, long-lasting construction.

What Is the Required Water Quality for Construction?

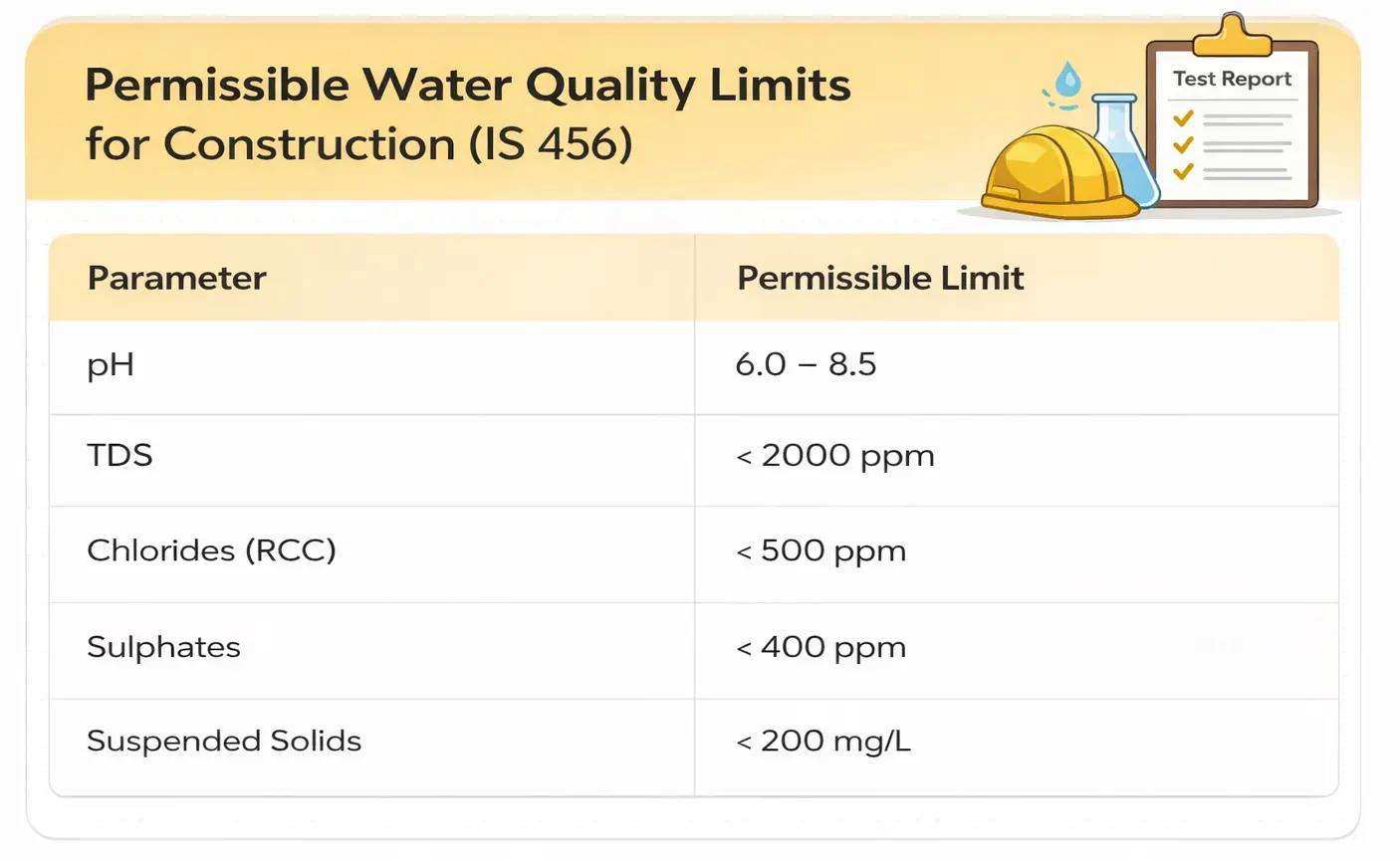

Construction water should meet these standards (IS 456:2000):

pH: 6.0 – 8.5

Water with a pH below 6 can corrode steel reinforcement, while water above 8.5 can disturb cement reactions. Maintaining the correct pH ensures proper cement hydration and long-term concrete durability.

TDS (Total Dissolved Solids): <2000 ppm

High TDS water means excess dissolved salts that slow cement setting and reduce concrete strength. Keeping TDS below 2000 ppm helps achieve consistent strength and prevents surface defects like efflorescence.

Chlorides (for RCC): <500 ppm

Chlorides directly attack steel reinforcement, accelerating corrosion within concrete. Limiting chlorides protects RCC structures and extends their service life.

- Sulphates: <400 ppm

Sulphates in water react with cement compounds, causing internal expansion in concrete. This leads to cracks, spalling, and long-term structural damage if limits are exceeded.

Hardness: Ideally <600 ppm

Excessive hardness increases water demand and disrupts the water–cement ratio. This reduces compressive strength and causes scaling or surface blemishes in concrete and plaster.

Suspended Solids / Turbidity: <200 mg/L

Muddy water, silt, and fine particles prevent proper bonding between cement and aggregates. Low turbidity ensures stronger concrete, better curing, and smoother finishes.

No Oil, Grease, or Heavy Metals

Oil, grease, and heavy metals interfere with cement hydration and delay strength development. Their absence ensures a uniform setting, structural stability, and long-term durability.

Why Is Muddy Water Harmful for Construction?

Mud, silt, and suspended particles present in construction water interfere with proper cement hydration and prevent strong bonding between cement and aggregates, a concern often observed on construction sites in Chennai, where water quality can vary. As a result, the concrete becomes weak and may develop cracks, honeycombing, poor plaster finishes, and shrinkage cracks over time. To avoid these issues and ensure durable construction, only clean, filtered, and sediment-free water should be used for mixing and curing. Using untreated, muddy water can also increase repair costs and shorten the structure’s overall lifespan. Proper water filtration helps achieve consistent concrete quality and long-term structural reliability.

How Do Silt and Turbidity Affect Construction Quality?

Fine suspended particles (clay, sand, debris) in water cause:

- Slower or incomplete cement hydration

- Reduced early and long-term compressive strength

- Microvoids, increased porosity, and water ingress

- Faster corrosion of steel reinforcement

- Poor workability, uneven slump, and surface defects

How Does High TDS Water Impact Construction?

Dissolved salts, such as Calcium and magnesium ions in water, sodium, chlorides, and sulphates, increase the total dissolved solids (TDS) level and slow down proper cement hydration. This reduces concrete strength, leading to visible problems such as efflorescence, scaling, and poor surface quality, and weakening plaster bonding. Over time, High TDS water accelerates corrosion of steel reinforcement and causes surface deterioration in concrete and masonry. To prevent these issues, construction water should have a TDS level below 2000 ppm, as per standards. Using RO-treated or properly filtered water helps lower TDS and ensures safe, durable construction, since untreated high-TDS water behaves like adding too much sugar to a cake mix, which affects how the structure sets and performs.

What Are the Effects of Heavy Metals in Construction Water?

Heavy metals such as lead, cadmium, chromium, and arsenic can interfere with cement hydration, delay setting, and reduce compressive strength and overall workability, an issue increasingly relevant in construction water sources across Chennai. Their presence can cause microcracks, uneven curing, and internal voids in concrete, making the structure weaker from the inside. Over time, heavy metals accelerate the corrosion of steel reinforcement and contribute to the chemical deterioration of concrete and masonry. These effects may not be immediately visible, but can significantly shorten the lifespan of the structure. To prevent such risks, water should be tested for heavy metals and treated before use to maintain structural integrity and long-term durability.

How Does Water Hardness Influence Construction Strength?

Calcium and magnesium ions in water, mainly due to permanent hardness from chlorides and Sulphates in water, disrupt the water–cement ratio and increase the amount of water needed for mixing. This leads to reduced compressive strength and improper bonding within the concrete. Over time, hard water can cause scaling, efflorescence, surface blemishes, cracking, and accelerated corrosion of steel reinforcement. To avoid these problems and ensure proper hydration and strong concrete, softened or properly filtered water should be used for construction. Regular water testing at construction sites helps monitor hardness levels and ensures compliance with recommended standards. Taking these preventive measures early improves structural durability and reduces long-term maintenance costs.

What is Permanent Hardness and Its Impact in Construction?

- Source of permanent hardness: Permanent hardness cannot be removed by boiling and is caused by Calcium and magnesium ions in water, such as chlorides, sulphates, and nitrates, present in water.

- Reduced concrete strength: High permanent hardness lowers both early-age and ultimate compressive strength by disturbing proper cement hydration.

- Poor bonding and porosity: They weaken the bonding between cement and aggregates, increasing porosity and allowing moisture and chemicals to penetrate more easily.

- Long-term structural damage: Over time, this leads to expansion, cracking, spalling, surface deterioration, and faster corrosion of steel reinforcement.

- Recommended solution: Using water softening or effective filtration ensures proper hydration, stronger concrete, and long-lasting structural durability.

Why is a Water Test Report Critical Before Construction?

A comprehensive water test helps identify key parameters, including pH, TDS, hardness, chlorides, sulphates, turbidity, and the presence of heavy metals, in construction water. It also determines whether the water meets the IS 456:2000 standards required for safe, durable construction. Based on the test results, the exact treatment or filtration needed can be identified to ensure proper cement hydration, strong bonding, and long-lasting structures. For accurate results, water samples should always be collected directly from the borewell or tanker before storage.

Where to Go for Reliable Water Testing in Chennai?

- Accredited NABL labs specialize in construction water testing. Click here for accredited NABL water labs in chennai.

- Technicians provide on-site services and collect samples.

- Water samples should be taken directly from the borewell or primary source.

- Labs check parameters like TDS, hardness, chlorides, sulphates, turbidity, and heavy metals.

- Expert guidance can be provided by water experts at Water Sparks ensure safe and suitable water for construction

Expert Water Quality Solutions – Water Sparks

- Free water consultation for borewell, tanker, or municipal sources to accurately assess construction water quality, especially for projects in Chennai.

- Identify high TDS water, hardness, chlorides, sulphates, silt, turbidity, and heavy metals.

- Provide effective filtration and treatment solutions for safe, durable construction.

- Ensure defect-free concrete, plaster, and masonry.

📞 Contact +91 9884366644 +91 9884257744, Expert guidance can be provided by water experts at Water Sparks ensure safe and suitable water for construction

FAQ : Water Quality for Construction

What type of water is safe for construction?

Water that is clean, clear, and free from harmful impurities is safe for construction. As per IS 456:2000, construction water should have a pH between 6.0 and 8.5, TDS below 2000 ppm, and should not contain excessive chlorides, sulphates, oil, grease, or heavy metals.

Can borewell water be used for construction?

Yes, borewell water can be used only after testing. In coastal and groundwater-dependent regions, borewell water often contains high TDS, hardness, chlorides, and sulphates, which can reduce concrete strength and accelerate steel corrosion if untreated.

What happens if high TDS water is used for concrete mixing?

High TDS water interferes with proper cement hydration, leading to:

Reduced compressive strength

Delayed or uneven setting

Efflorescence and surface scaling

Long-term durability issues

That is why construction water TDS should remain below 2000 ppm.

Is hard water acceptable for construction?

Moderately hard water may be acceptable, but excessive hardness increases water demand, disrupts the water–cement ratio, and reduces compressive strength. Hardness should ideally remain below 600 ppm for construction use.

Is muddy or turbid water harmful for construction?

Yes. Muddy water contains silt, clay, and suspended solids that prevent proper bonding between cement and aggregates. This can cause honeycombing, cracks, poor plaster finish, and reduced concrete strength.

How do chlorides in water affect reinforced concrete?

Chlorides attack steel reinforcement by breaking its protective oxide layer. This leads to rapid corrosion, expansion of steel, cracking of concrete, and eventual structural failure. For RCC, chloride levels should not exceed 500 ppm.

Why are sulphates dangerous in construction water?

Sulphates react with hydrated cement compounds to form expansive products like ettringite. This causes internal expansion, cracking, spalling, and long-term deterioration of concrete if sulphate levels exceed 400 ppm.

Do bacteria in water affect concrete strength?

Bacteria generally do not significantly affect concrete strength because cement has high alkalinity. However, water containing organic matter, oils, or sewage contamination should be avoided as it may cause surface defects and delayed setting.

What water tests are required before construction?

Before construction, water should be tested for:

pH

TDS

Hardness

Chlorides

Sulphates

Turbidity

Heavy metals (if industrial or coastal source)

These tests ensure compliance with IS 456:2000 standards.

How can poor construction water quality be treated?

Depending on test results:

Sedimentation & filtration remove mud and turbidity

Water softeners reduce hardness

RO systems lower high TDS and sulphates

Activated carbon removes organic contamination

Proper treatment ensures durable, defect-free construction.