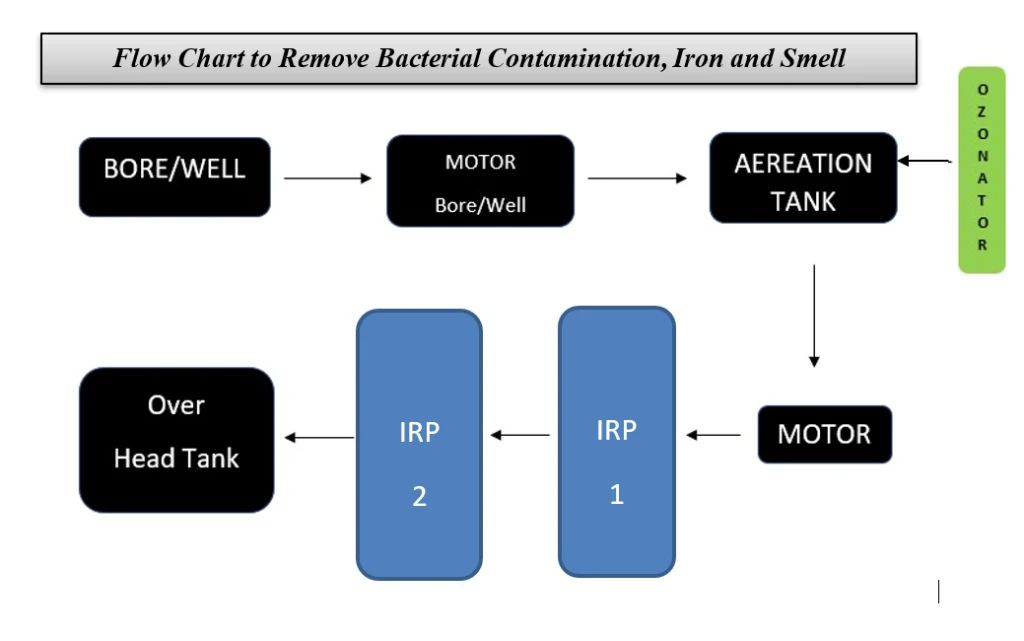

Ozonator with Iron Removal Plant

The combination of an ozonator and an iron removal plant can be an effective solution for water treatment. Let’s explore how each component works and how they complement each other:

PROCESS 1:

- Ozonator: An Ozonator is a device that generates ozone gas (O3). Ozone is a powerful oxidizing agent that can effectively disinfect water and remove various contaminants. When ozone is introduced into water, it reacts with organic matter, pathogens, and certain inorganic compounds, breaking them down into harmless byproducts. The ozonation process can eliminate bacteria, viruses, algae, and other microorganisms, as well as reduce the levels of pesticides, pharmaceuticals, and odors in the water.

PROCESS 2:

- Iron Removal Plant: Iron is a common water contaminant that can cause aesthetic and operational issues. High iron concentrations often result in a reddish-brown color, metallic taste, and staining of plumbing fixtures and laundry. An iron removal plant utilizes various methods to remove iron from water, such as oxidation and filtration. The process involves oxidizing the dissolved ferrous iron (Fe2+) into ferric iron (Fe3+), which then precipitates and can be filtered out or settled. Different techniques like aeration, chemical oxidation, or catalytic media are employed in iron removal plants to effectively treat water-containing iron.

Combining an ozonator with an iron removal plant can enhance the overall water treatment process. Here’s how they work together:

- Oxidation: Ozone has strong oxidizing properties, and when introduced into water, it can aid in the oxidation of ferrous iron to ferric iron. This pre-oxidation step can facilitate the subsequent removal of iron in the iron removal plant, making the process more efficient.

- Disinfection: Ozone is highly effective in killing bacteria, viruses, and other microorganisms present in water. By incorporating an ozonator before the iron removal plant, any biological contaminants that might interfere with the iron removal process can be eliminated, ensuring better water quality.

- Organic Matter Removal: Ozone can break down organic compounds present in the water, including some naturally occurring organic matter that may contribute to iron-related issues. By reducing the organic load, the efficiency of the iron removal plant can be improved, as organic matter can interfere with the filtration process.

By combining the ozonation process with the iron removal plant, you can achieve a comprehensive water treatment system that addresses both microbial and iron-related concerns. It is important to design and operate the system based on the specific water quality parameters and requirements to ensure optimal performance. Consulting with water treatment professionals or engineers experienced in ozonation and iron removal plants.

An ozonator, also known as an ozone generator, is a device used to produce ozone gas (O3). Ozone is a powerful oxidizing agent and disinfectant that can be used to remove bacterial contamination from water. The process of ozone disinfection works through several steps:

- Ozone Generation: The ozonator uses either corona discharge or ultraviolet (UV) light technology to generate ozone gas. In corona discharge, electrical discharges pass through oxygen molecules, splitting them into individual oxygen atoms. These atoms then combine with other oxygen molecules to form ozone. In UV light technology, ultraviolet radiation breaks oxygen molecules apart, creating ozone.

- Injection: The ozone gas is injected into the water that needs to be treated. This can be done through a diffuser or contact chamber where the ozone is mixed with the water.

- Disinfection: Ozone acts as a powerful oxidizing agent and disinfectant. When it comes into contact with bacteria, viruses, and other microorganisms in the water, ozone damages their cellular structure and inhibits their ability to grow and reproduce. This process effectively kills or inactivates the microorganisms present in the water.

- Decomposition: Ozone is highly reactive and has a short life span in water. After disinfection, any remaining ozone in the water quickly decomposes back into oxygen without leaving any harmful residues or by-products.

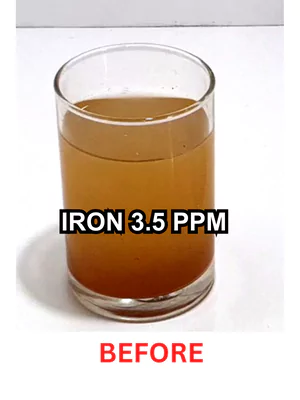

Iron water can exhibit various colors depending on its oxidation state and the presence of other substances. The phenomenon of iron water changing from white to yellow or brown can be attributed to the oxidation and precipitation of iron compounds.

- Dissolved Ferrous Iron (Fe2+): When water containing dissolved ferrous iron (Fe2+) is initially drawn from a well or tap, it often appears colorless or slightly white. Ferrous iron is soluble in water and remains in its dissolved form. At this stage, the iron concentration may be relatively low, and the water may appear clear.

- Oxidation of Ferrous Iron to Ferric Iron (Fe3+): Upon exposure to air or oxygen, dissolved ferrous iron undergoes oxidation and is converted into ferric iron (Fe3+). This oxidation reaction can be facilitated by factors such as aeration, agitation, or the presence of catalysts. The oxidation of ferrous iron to ferric iron is a key step in the iron removal process.

- Formation of Iron Oxides/Hydroxides: Ferric iron is insoluble in water and tends to form solid compounds known as iron oxides or iron hydroxides. These compounds can vary in color, typically appearing yellow, orange, or brown. As the ferric iron precipitates out of the water, it forms visible particles or floc. These iron particles give the water a characteristic yellow or brown tint, making it visually apparent that iron is present in the water.

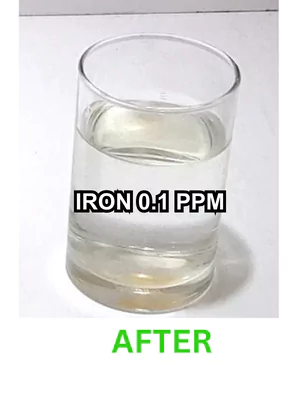

- Aggregation and Settling of Iron Floc: The iron floc, composed of iron oxides or hydroxides, tends to aggregate and settle due to its increased density. This settling process can occur in settling basins or sedimentation tanks, allowing the iron floc to separate from the water. As the iron floc accumulates at the bottom of the basin or tank, the water above becomes clearer and less discolored.

It’s important to note that the intensity of the yellow or brown color in iron water can vary depending on the concentration of iron, the oxidation rate, and the presence of other substances. Factors such as pH, temperature, and the presence of dissolved organic matter or minerals can influence the color of iron water as well.

The process of iron removal in a water treatment plant aims to oxidize and precipitate the dissolved ferrous iron, followed by the removal of the resulting iron particles through settling and filtration steps. This helps improve the visual appearance and taste of the water, as well as prevents the formation of rust deposits or stains in plumbing fixtures and appliances.

Iron Removal Plant

Combining an ozonator with an iron removal plant can enhance the overall water treatment process. Here’s how they work together:

Oxidation: Ozone has strong oxidizing properties, and when introduced into water, it can aid in the oxidation of ferrous iron to ferric iron. This pre-oxidation step can facilitate the subsequent removal of iron in the iron removal plant, making the process more efficient.

Disinfection: Ozone is highly effective in killing bacteria, viruses, and other microorganisms present in water. By incorporating an Ozonator before the iron removal plant, any biological contaminants that might interfere with the iron removal process can be eliminated, ensuring better water quality.

Organic Matter Removal: Ozone can break down organic compounds present in the water, including some naturally occurring organic matter that may contribute to iron-related issues. By reducing the organic load, the efficiency of the iron removal plant can be improved, as organic matter can interfere with the filtration process.

By combining the ozonation process with the iron removal plant, you can achieve a comprehensive water treatment system that addresses both microbial and iron-related concerns. It is important to design and operate the system based on the specific water quality parameters and requirements to ensure optimal performance. Consulting with water treatment professionals or engineers experienced in ozonation and iron removal is recommended for designing and implementing such a system.