Water Sparks Customized Products

Customization of water treatment plants involves tailoring the design, processes, and equipment to meet specific requirements and conditions of a particular location or application. Here are some key aspects of customization for water treatment plants as we are RO Plant Manufacturers, Iron removal Plant Manufacturers, Water Softener Plant Manufacturers and Water Treatment Plant Manufacturers

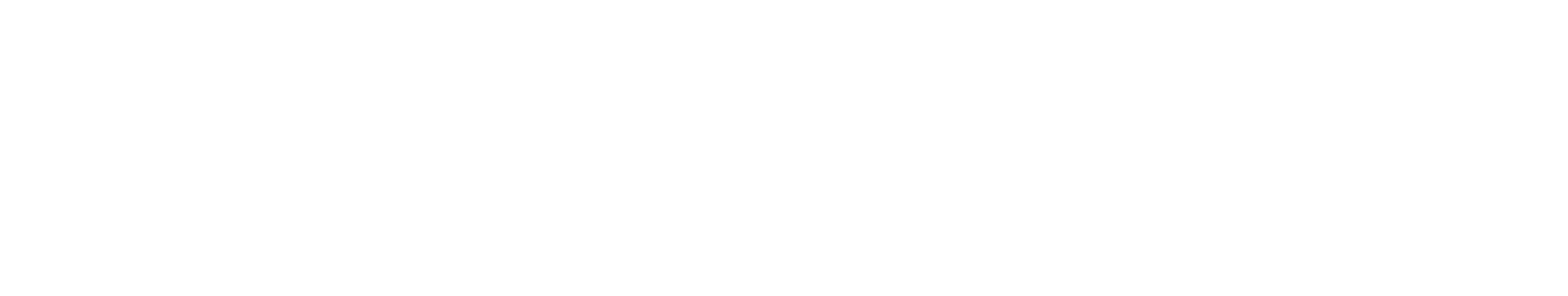

Water Source Analysis:

Before designing a customized water treatment plant, an analysis of the water source is necessary. Factors such as the quality of the raw water, its composition, and seasonal variations must be considered. This analysis helps determine the appropriate treatment processes and technologies required.

Treatment Process Selection:

Depending on the water quality parameters and desired water quality standards, specific treatment processes are selected. Common processes include coagulation, flocculation, sedimentation, filtration, disinfection, and advanced techniques like Whole House Iron Removal Plants, Whole House Water Softener Plants, Whole House RO Plant (Reverse Osmosis), Ultraviolet (UV) treatment, or Ozonation. The selection is based on the specific contaminants present and the desired water quality outcomes.

Aeration

Ozonation

Chlorination

Air Blower & Diffuser

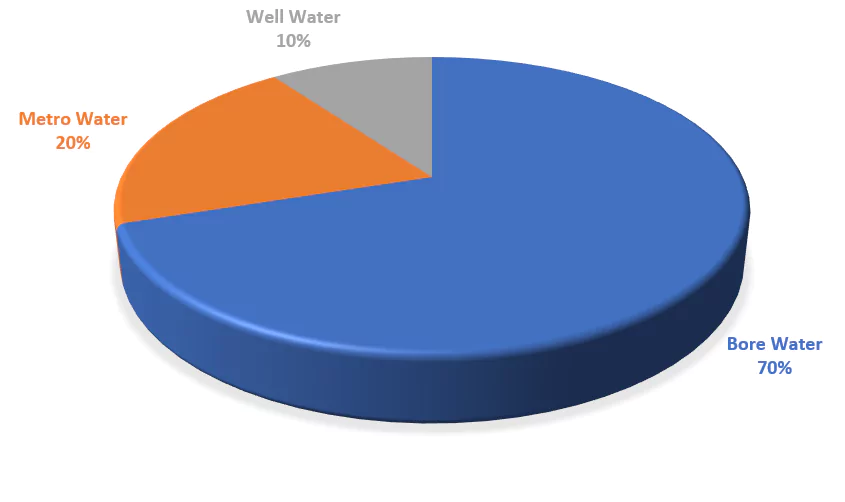

Plant Configuration:

Customization involves designing the treatment plant layout and configuration to optimize the treatment processes and accommodate site-specific conditions. This includes determining the size and number of treatment units, considering space constraints, and integrating pre-treatment and post-treatment processes effectively.

COMPACT SIZE

HASSLE FREE TURN KEY PROJECT

PRE-PLANNED PROJECT

Equipment and Technology:

The selection of equipment and technology is critical for customization. The choice of pumps, valves, filters, membranes, chemical dosing systems, and monitoring instruments depends on factors such as water flow rates, water quality parameters, and treatment process requirements. Specialized equipment or innovative technologies might be necessary for addressing unique challenges.

Automation and Control Systems:

Customized water treatment plants often incorporate automation and control systems to optimize process efficiency and ensure consistent water quality. This includes the use of sensors, programmable logic controllers (PLCs), human-machine interfaces (HMIs), and data monitoring systems to regulate and monitor treatment processes in real time.

Compliance with Regulations:

Customized water treatment plants should be designed to meet local, regional, and national regulations and standards governing water quality. The treatment processes and technologies must comply with the permitted limits for various contaminants to ensure the safety of the treated water.

Future Scalability and Flexibility:

Customized water treatment plants should also be designed with scalability and flexibility in mind. Consideration should be given to potential future expansion needs or changes in water quality requirements, allowing for easy modifications or upgrades to meet evolving demands.

As a Water Treatment Plant Manufacturers our customization of water treatment plants requires a comprehensive understanding of the specific water source, treatment objectives, and local regulations. By tailoring the design, processes, and equipment, it is possible to develop efficient and effective solutions for water treatment in various applications and locations.